If you’re a builder seeking consistent, high-quality AAC blocks or an investor exploring the profitable AAC block manufacturing business, understanding the AAC blocks manufacturing process is critical. Autoclaved Aerated Concrete (AAC) blocks are renowned for their lightweight, eco-friendly, and energy-efficient properties—but their performance hinges on a precise, streamlined production workflow.

This guide breaks down the AAC blocks manufacturing process in simple terms, from raw material preparation to final packaging. We’ll highlight key steps, equipment needs, quality control checks, and why partnering with a trusted AAC block production line manufacturer ensures success. Whether you’re evaluating AAC blocks for your next project or planning to start a plant, this article covers everything you need to know.

Overview: What Is the AAC Blocks Manufacturing Process?

The AAC blocks manufacturing process is a blend of chemical reactions, precision engineering, and automated production. Unlike traditional clay bricks (fired at high temperatures) or concrete blocks (cast and air-cured), AAC blocks are made by mixing natural/industrial materials, foaming the mixture, and curing it in high-pressure autoclaves.

The entire process takes 8–12 hours (from raw material to finished block) and is highly scalable—adaptable for mini plants (30,000–100,000 m³/year) for local markets or large-scale lines (200,000+ m³/year) for national/export supply. The result is a uniform, porous block that outperforms traditional materials in strength, insulation, and sustainability.

Step-by-Step AAC Blocks Manufacturing Process

1. Raw Material Preparation & Batching (The Foundation of Quality)

The process starts with sourcing and preparing core ingredients—AAC block raw materials include cement, lime, fly ash (or sand/slag), aluminum powder (foaming agent), and water. Here’s how it works:

- Crushing & Grinding: Fly ash (or sand) and lime are crushed into fine powder using a ball mill—critical for ensuring uniform mixing and chemical reactions.

- Storage & Handling: Ingredients are stored in sealed silos to prevent moisture absorption (moisture ruins the foaming process). Modern AAC block making plants use automated silo systems with level sensors for inventory control.

- Precision Batching: A PLC-controlled batching system weighs ingredients (e.g., 60% fly ash, 20% cement, 15% lime, 0.1% aluminum powder) with ±1% accuracy. This step eliminates human error and ensures consistent block quality—key for winning builder contracts.

For investors, local raw material availability (e.g., fly ash in India, sand in Nigeria) reduces costs and simplifies this step. Trusted manufacturers customize batching formulas to match regional materials.

2. Mixing & Foaming (Creating the Porous Structure)

Once batched, ingredients are transported to a high-speed mixer, where water is added to form a smooth slurry. The magic of AAC blocks happens here:

- Foaming Reaction: Aluminum powder is added to the slurry. It reacts with calcium hydroxide (from lime) to release hydrogen gas, creating millions of tiny, uniform air bubbles.

- Slurry Expansion: The mixture expands to 2–3 times its volume as bubbles form. This expansion gives AAC blocks their signature lightweight (500–700 kg/m³) and insulation properties.

- Consistency Control: The mixer runs for 3–5 minutes to ensure even bubble distribution. Too little mixing causes uneven density; too much breaks bubbles—ruining the block’s structure.

Automated mixers in modern AAC block production lines adjust speed and mixing time based on real-time slurry viscosity data, guaranteeing consistency batch after batch.

3. Casting & Rising (Shaping the Blocks)

The foamed slurry is poured into large, rectangular molds (typically 6m × 1.2m × 0.6m) using a casting machine. Here’s what happens next:

- Mold Preparation: Molds are coated with a release agent to prevent sticking. Reusable steel molds are standard in commercial plants for durability.

- Rising Period: The slurry sits in molds for 2–3 hours at 40–50°C. During this time, the hydrogen gas escapes, and the mixture sets into a solid, porous “cake” (called a green block).

- Demolding: Once set, the green block is removed from the mold using a crane. It’s now strong enough to handle but still soft enough for cutting.

This step is critical for block size accuracy—molds are customized to produce standard sizes (e.g., 600×200×100mm) or project-specific dimensions.

4. Cutting (Precision for Uniform Blocks)

Green blocks are transported to a wire cutting machine—one of the most important pieces of AAC block manufacturing equipment. Here’s how it works:

- Multi-Wire Cutting: The block is cut into individual AAC blocks using a grid of thin, high-tensile steel wires. This process ensures precise dimensions (±2mm tolerance) and smooth edges—no chipping or waste.

- Custom Cuts: The machine can be programmed to cut blocks of different sizes (e.g., thin partitions, thick load-bearing walls) without changing molds, increasing production flexibility.

- Waste Recycling: Trimmed edges and offcuts are crushed and reused as raw material, making the process 95% waste-free—another eco-friendly advantage of AAC block manufacturing.

5. Autoclaving (Curing for Strength & Durability)

Autoclaving is the step that differentiates AAC blocks from other aerated concretes. The cut blocks are loaded into high-pressure autoclaves for final curing:

- High-Temperature & Pressure: Autoclaves operate at 180°C and 10–12 bar pressure for 8–10 hours. This triggers a chemical reaction (hydrothermal synthesis) that strengthens the block’s structure.

- Uniform Curing: Autoclaves use steam to ensure even heat distribution. Modern models have computerized controls to adjust temperature/pressure for different block sizes.

- Result: After autoclaving, AAC blocks achieve compressive strength of 2.5–5 N/mm²—strong enough for load-bearing walls—while retaining their lightweight and insulation properties.

For investors, choosing the right autoclave (dual-fuel, energy-efficient) reduces operating costs. Trusted manufacturers offer autoclaves tailored to local energy sources (e.g., gas + electricity for Pakistan’s power outages).

6. Quality Control & Packaging (Ready for Delivery)

The final steps ensure only top-quality blocks reach customers:

- Quality Checks: Blocks are inspected for strength (compression testing), density, dimensions, and thermal conductivity. Defective blocks are recycled—no subpar products leave the plant.

- Drying: Blocks are air-dried for 24 hours to remove surface moisture, preventing mold during storage.

- Packaging & Stacking: Blocks are stacked on pallets and wrapped in weatherproof plastic (critical for monsoon regions like Southeast Asia). Semi-automatic or fully automatic stacking machines reduce labor costs.

For builders, consistent quality means fewer delays and reworks. For investors, strict quality control builds brand trust and repeat business.

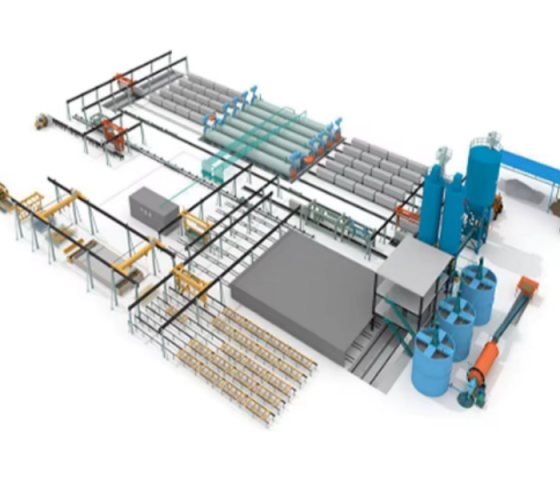

Key Equipment for AAC Blocks Manufacturing Process

To implement this process efficiently, you’ll need a turnkey AAC block production line with these core machines:

- Ball mill (raw material grinding)

- PLC-controlled batching system

- High-speed mixer

- Casting machine & molds

- Wire cutting machine

- Autoclave

- Stacking & packaging equipment

The right equipment mix depends on your production capacity (mini vs. large plant) and budget. Trusted manufacturers offer customized packages—from semi-automatic lines for startups to fully automatic systems for large-scale operations.

Why the AAC Blocks Manufacturing Process Is Profitable for Investors

The AAC blocks manufacturing process offers unique advantages for entrepreneurs:

- Low Operating Costs: Automated production reduces labor needs (5–10 workers per shift vs. 20+ for clay brick plants). Waste recycling and local raw materials cut input costs.

- High Demand: Governments worldwide ban clay bricks (e.g., India, Pakistan, Nigeria) to protect soil, driving demand for AAC blocks. The global AAC market is growing at 8.2% CAGR (Grand View Research).

- Scalability: Start with a mini plant (30,000 m³/year, $100k–$1M investment) and upgrade to a large line as demand grows. ROI is typically 12–24 months.

- Eco-Friendly Incentives: Many countries offer tax breaks, subsidies, and low-interest loans for sustainable manufacturing (e.g., EU’s Green Deal, India’s PLI scheme).

Final Thoughts: Partner With a Trusted AAC Block Production Line Manufacturer

The AAC blocks manufacturing process is streamlined, eco-friendly, and highly profitable—but success depends on choosing the right equipment and partner. A trusted AAC block production line manufacturer will customize the process to your local market (raw materials, energy sources, block sizes), provide installation and training, and offer after-sales support.

Whether you’re a builder looking for reliable AAC blocks or an investor ready to start a profitable business, we’re here to help. Our turnkey AAC block production lines are designed for capacities 30,000–600,000 m³/year, with global support and localized solutions.